Our Story

This chapter was chartered as one of the first chapters in Florida. The chapter was established in February of 1956 as an extension of the Atlanta Chapter. The chapter charter was presented to our first president, Karl Hickman at the Columbia Restaurant in Ybor City, Tampa.

In 1959, the merger of ASHAE and ASRE resulted in formation of the Florida West Coast Chapter of ASHRAE after the local ASRE chapter and the Central Florida members of the Jacksonville Chapter of ASHRAE joined.

By the end of 1959, the chapter meetings attracted over 100 attendees with a series of panel discussions on the relationships of engineers, contractors, architects and owners. Since then, the Florida West Coast Chapter has grown to over 360 members and continues to provide essential resources for sustainable design, construction and operation of buildings. You can find a copy of the original charter and a list of the first chapter officers and board members in the links below.

ASHRAE Celebrates its 125th Anniversary

ASHRAE celebrating its 125 year history all throughout 2020-2021

125th ASHRAE anniversary article:

ASHVE Organizational Meeting September 1894

Twenty-five inivitees met at the offices of Heating and Ventilation [magazine], 146 World Building, New York, Thursday, August 2, 1894. The first regular meeting was called to order at 3 P. M., September IO, 1894, at the Broadway Central Hotel, New York. Roll call found that 75 persons had become charter members

Some more on the 125 year History of ASHRAE / ASHVE

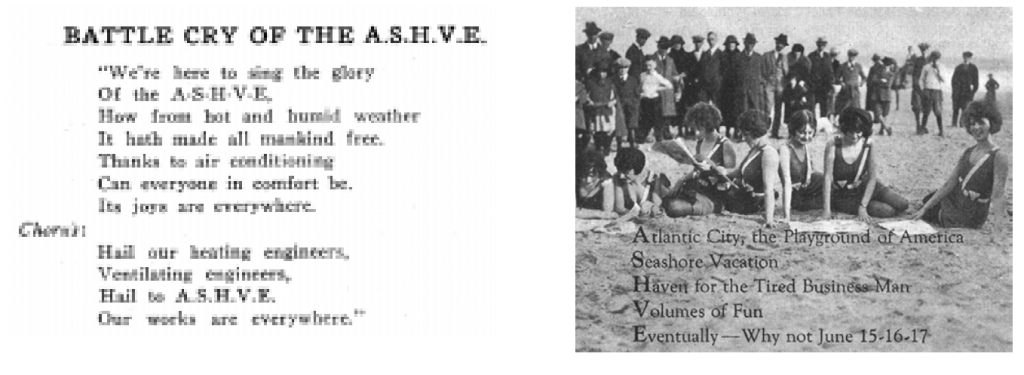

The Society had a song set to the music of the Battle Hymn of the Republic (words by Washington

Chapter, performed at 1940 Annual Meeting in the District of Columbia)

By Robert P. Sutton

1995 – Chapter Historian

Chairman, Historical Committee, Florida West Coast Chapter, ASHRAE

(This History of a Person was submitted June 1, 1995 for inclusion in the activities of the Florida West Coast Chapter of ASHRAE, Historical Committee Centennial Year Activities, for the 1994-1995 Fiscal Year.)

Robert J. Clark grew up in the Cleveland, Ohio area and graduated from high school in l931. After high school, Bob worked in construction for several years on various commercial and industrial projects. He was married to his present wife, Dodie, after she had finished college in 1937. He had saved some of the money he earned in his construction jobs and decided to enroll in college and get his degree. He graduated from Case Institute of Technology with a B.S. in engineering in 1941.

During 1941, he was still working in construction on a new chemistry building on the college campus in his senior year. He was superintendent of construction on the chemistry building and was also working on a new Plant No. 3 for the Jack and Hientz Co., an aircraft instrument company, when W.W.II broke out. It seemed that Bob could go in to the service and was even offered a Lt. Commander commission in the Seabees because of his wealth of construction experience at the time. But, his experience was too valuable. Bill Jack, President of Jack and Hientz, called him into his office and informed him that Col. Mike Moriarty, Chief of Procurement had informed the company that they had just received a contract for 3000 Norden Bomb Sights. This meant that a new 5-acre plant had to be built especially for this project. The problem was that the plant had to be built in two months in order to meet production schedules for the bombsights. The company wanted Bob to be part of the construction team for the building of this new plant.

[toggle type=”white” title=”History Continued…” ]The construction for the plant required a lot of manpower and special resources to meet its deadline. The work crews worked 24 hours a day, seven days a week. They put out a call for men and in the first week they had 10 teams. Several teams were located on the west coast to procure timber for the plant. The plant was built from slow burning mill type construction timbers, 12×12, 12×14, and 12×18, because steel was at a premium due to the war. The teams in Oregon and Washington bought timber and they would have a person ride back with the timber carrying his sleeping and camping gear. This was the only way they could be sure to get the timbers all the way back to the plant. They finally finished the plant construction in an incredible time of 47 days.

The plant was special in that it used cascaded refrigerant systems. Bob had worked in refrigerated meat and meat product plants and had some experience with ammonia systems. However, these bombsights required special construction techniques. The instruments would experience 120 degree F temperatures on the ground and minus 60 degrees ten minutes later when the planes were in the air. This required that the instrument had to be verified and calibrated in the laboratory test chamber and that they simulate these conditions in the plant. Bob said that there was no information in 1943 on this kind of special application and they went to ASHRAE to get the job done. They called in the York Corporation for the equipment. Using Freon 12 they built a three stage cascaded system. Cost meant nothing at that time, so they had ordered a 200 hp Fuller rotary compressor. In an interesting footnote, Bob remembered that some projects had higher priority over others during the war. One day a young Lieutenant came in and confiscated that compressor for the “Manhattan Project”. Eventually they got their own compressor and built their system.

The Norden bombsights were put together with aluminum rivets and the rivets had to be set. This required that they be set at temperatures less than the operating conditions of the instrument. A special chamber was built that pulled the rivets down to minus 90 degrees F so they could set the rivets. This chamber was about a big as the bombsight, 18″x12″x24″.

The Jack and Hientz Company built several thousand bombsights. They also manufactured an automatic pilot that was linked to the bombsights. At first the initial 3000 bombsights were contracted at $3,000 for the Norden Co., but that price was reduced to $ 1,700 apiece after their first shipment. The Norden Co. hired Jack and Hientz because they had one of the first air-conditioned plants. This was their secret to manufacturing the bombsights at a lower cost. With the air conditioned plant the manufacturing could hold their tolerances easier. No one else could do that at the time. Eventually the price became too low and with the war ending the plant slowly stopped production.

At the time of the war ending, Bob was looking to move to Florida where he and his wife had spent one of their vacations on the central west coast, in Clearwater, Florida. He had learned that many of the manufacturers were looking for representation in the Florida area. There was virtually no air conditioning in many of areas in Florida, to speak of, and Bob seized the opportunity to represent air conditioning products. Bob moved to Florida in 1946 and started Clark Equipment Sales. Bob started off representing American Air Filter, Canard, Tuttle and Bailey, and many other airside products. His company was one of the pioneers in application of the packaged air-handling units.

Bob would spend three weeks of each month on the road: one week in Miami; another in Jacksonville; and one week in Orlando and Tallahassee. By 1950 Bob had offices in Miami, Jacksonville, and Clearwater, and had 22 employees. He called on engineers and contractors throughout Florida.

Bob became an ASHRAE member in 1943 and he recalls that he attended many ASHRAE functions in Miami and would always attend the annual winter meeting with several of his salesmen. He also was instrumental in helping to set up the first annual air conditioning conference in 1948 on the campus of the University of Florida in Gainesville, Florida. This conference was one of the first of its kind in the area and had representatives from all over the country attend. The Annual Air Conditioning Conference continued to be a premier event and was held on the University of Florida Campus for over 20 years into the 70’s.

Bob and others in Florida helped lobby the State of Florida Legislature to get public schools air-conditioned and eventually Bob sold equipment on one of the first schools in his area to be air-conditioned. That school was the Oak Grove Elementary School, in Clearwater, Florida. The system was unit ventilators with chilled water. Prior to that time the schools had mandates for fixed percentages of operating and fixed window sashes on the typical classroom. When air conditioning came around they still maintained this guideline for windows for many years, just in case the air conditioning wasn’t working.

Bob also had other businesses in Florida as a result of his contacts in the area. He sold and serviced Thunderbird boats, had a diving shop, and taught skin diving.

In 1966, Bob sold the business in Miami and by 1970 was fully retired. He has maintained his membership in ASHRAE and was awarded his 50-year certificate in 1993. He recently attended the Florida West Coast Chapter History Night meeting in March 1995 and was highlighted as one of the outstanding guests in attendance that evening. .

Bob is a very active traveler and has been to many corners of the world with his wife since starting his retirement. We are pleased to see Bob is still involved with ASHRAE and are pleased to have had the opportunity to interview him as one of our prominent members. His company was very instrumental in the development of the HVAC industry in Florida and in the Tampa Bay area.